eliptical brinelli hardness test|brinell hardness testing error : trade Brinell test procedure. In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves . Crie sua rifa. e. arrecade muito mais. pela plataforma! Potencialize sua arrecadação criando uma página do seu sorteio virtual, com temas especiais para rifas da sorte, solidárias, .

{plog:ftitle_list}

29/10/2023 • 03:08. Topo. + Milionária: todos os sorteios oferecem, no mínimo, R$ 10 milhões. Resultado do +Milionária. Veja também. Bolsonaro pediu ação antes das .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear .

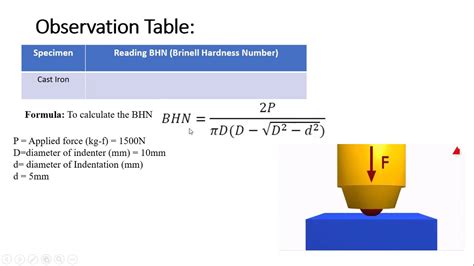

A Brinell hardness result measures the permanent width of indentation produced by a carbide indenter applied to a test specimen at a given load, for a given length of time.Brinell test procedure. In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves .Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, .According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the Brinell hardness (HBW).

The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. .Applications for Brinell Methods Brinell testing is suitable for measuring the hardness of rela-tively soft materials, including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter and high load helps to minimize the effect of surface irregu-larities and yields more accurate hardness values. Soft Materials .

how to determine brinell hardness

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter. General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. This test is used to .The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10. It is typically used to test materials with a structure or surface too coarse to be tested by any other test method, for example castings and forgings. Brinell tests often use a very high test load (3000 kgf) and a 10mm diameter indenter so that the .The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the . However, there’s another test known as the Brinell hardness test, named after Swedish engineer Johan August Brinell. The ASTM test for Brinell hardness is ASTM E10, but please note that this test is specifically for metallic objects – there is no ASTM standard for measuring the Brinell hardness of wood.Brinell test methods are defined in the following standards-ASTM E10; ISO 6506; JIS Z 2243 ; Equipment Required. Brinell hardness tester RAB-250; Brinell microscope; Indentors (2.5mm and 5mm ball) Brinell Test Machine Description. The Brinell Hardness Tester consists of a loading system, the main screw, and a dial gauge.Brinell tests have long been the preferred method of assaying the hardness of metals during forming operations. The general significance of the test has been codified in empirical laws, especially those of Meyer, O’Neill and Tabor. On the other hand, the indentation of elastoplastic media by a ball has never been thoroughly analysed in the context of modern mechanics of .

The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:Is 1500:2005 ISO 6506-~: 1999 4.1 The Brinell hardness is denotedby HBW. NOTE Informerstandards,in cases when a steel ballhad been used,the Brinellhardnesswas denotedby HB or HBS. 4.2 The letters HBW are preceded by the hardness value and supplemented by an index indicating the test

Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg .Brinell hardness test charts. The approximate Brinell number for loads are: Load (kg) Brinell hardness number: 500: 26 – 100: 1500: 80 – 300: 3000: 160 – 600: While the Brinell hardness test is most commonly used to test metals and alloys, it can be used on other materials too.Hardness Test Analysis on ST 37 Steel Plate Material and Aluminum Using the Brinell Test Method Franklin Taruyun Hudeardo Sinaga 1 , Eka Putra Dairi Boangmanalu 2 *, AnggaThe Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. This test involves pressing a Brinell indenter against a test specimen under a specified load and time duration. Typically, a hardened Tungsten steel ball, with varying force ranges based on material .

Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. Below are some key industries where the Brinell Hardness Test is commonly employed. 1. Manufacturing

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).4.1 The Brinell hardness test is an empirical indentation hardness test. Brinell hardness tests provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, or other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

The Brinell Hardness Test is a straightforward process that is often applied to materials with rough structures, like cast irons or forged metal samples. During the test, a 5mm or 10mm round carbide ball is pressed into the material using a very high test load, usually between 750kg and 3000kg. This action creates an indentation that is . The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum.

As in Knoop and Vickers testing, Brinell Testing by nature is a labor-intensive and manual process that, in its conventional state, necessitates constant human intervention and processing. Since the traditional Brinell test has a single, controlled test force made with a specified diameter tungsten carbide ball, the

Prosedur Hardness Test : 1. Brinell Hardness Test. Hal yang perlu diperhatikan pada saat pengujian hardness Brinell adalah sebagai berikut : Spesimen harus memenuhi persyaratan : – Rata dan halus. – Ketebalan minimal 6 mm. – Bisa ditumpu dengan baik dan permukaan uji harus horizontal.

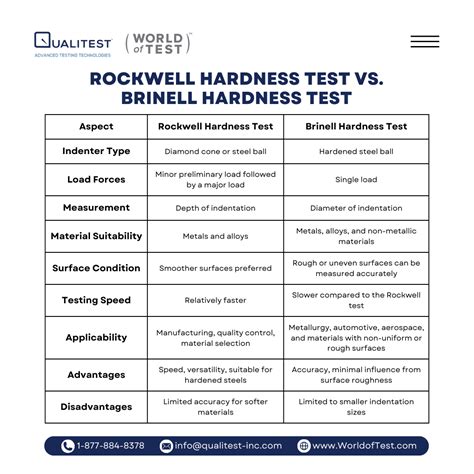

brinell vs rockwell hardness test

Resultado da Mount Lemmon ski resort transforms into the winter jewel of Tucson Arizona every year from late November through to early April. Stay up to date with all the latest snow and seasonal storms by checking out our Mount Lemmon web cam. These snow cams are perfectly placed all over the mountain and ski .

eliptical brinelli hardness test|brinell hardness testing error